What O-ring groove?

How to Select an O-Ring for a Groove

Choosing the correct O-ring for a groove is essential to ensure reliable sealing. Here's a step-by-step explanation:

1. Determine the Type of Application

First, define whether the sealing application is:

-

Static – no relative motion between parts (e.g., face seal on a flange)

-

Dynamic – parts move relative to each other (e.g., piston or rotary seal)

Static applications allow more flexibility in design, while dynamic ones require tighter tolerances and specific materials.

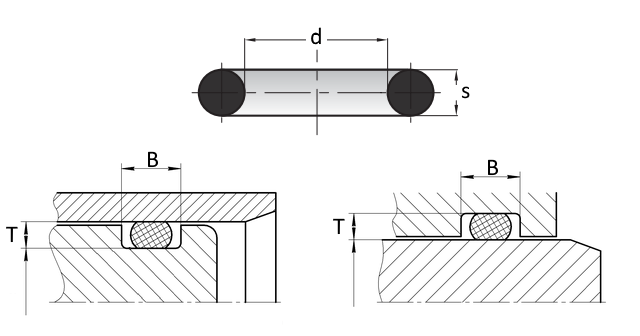

2. Measure the Groove Dimensions

You need to know:

-

Groove Diameter (D): Either the bore (inside) or shaft (outside) diameter

-

Groove Width (B): The axial width of the groove

-

Groove Depth (T): The radial depth of the groove

Make sure the groove surface is smooth and deburred to prevent O-ring damage during installation or operation.

3. Choose the Right O-Ring Size

O-rings are defined by:

-

ID (Inner Diameter)

-

CS (Cross Section) – the thickness of the ring

Selection rules:

-

For internal (shaft) sealing: The O-ring ID should be slightly smaller than the groove diameter (to ensure stretch and fit)

-

For external (bore) sealing: The O-ring ID should be slightly larger than the groove diameter (to ensure compression)

Typical compression:

-

Static applications: 10–30% radial compression

-

Dynamic applications: 10–20% radial compression (lower to reduce wear)

4. Verify Groove Fit

Ensure there is enough space in the groove:

-

Groove width (B) should allow the O-ring to expand slightly under pressure without extrusion

-

Groove depth (T) should compress the O-ring by the required percentage

Always account for tolerances and thermal expansion of materials.

5. Select the Right Material

Choose an O-ring material based on:

-

Operating temperature

-

Media (e.g., oil, water, fuel, chemicals)

-

Pressure and motion (static/dynamic)

Common O-ring materials:

-

NBR (Nitrile): Good for oil and fuel, affordable

-

FKM (Viton®): High chemical and heat resistance

-

EPDM: Ideal for water, steam, and weathering

-

Silicone: Excellent temperature flexibility, but lower mechanical strength

6. Use Standards and Manufacturer Charts

Refer to standards such as:

-

ISO 3601 (international)

-

AS568 (USA)

-

Manufacturer catalogs (e.g., Parker, Trelleborg, Kalrez)

These standards provide recommended groove dimensions for each O-ring size.

Example:

For an O-ring 2.5 mm thick (CS), the groove dimensions might be:

-

Width (B): ~3.1 mm

-

Depth (T): ~1.9 mm

-

Compression: ~24%

The table gives the groove parameters for static use (depth and width):

| s O-ring thickness | T groove depth | B groove width |

| 1,5 | 1,1 | 1,9 |

| 1,6 | 1,2 | 2,1 |

| 1,78 | 1,3 | 2,3 |

| 2 | 1,5 | 2,6 |

| 2,4 | 1,8 | 3,1 |

| 2,5 | 1,9 | 3,2 |

| 2,62 | 2 | 3,4 |

| 3 | 2,3 | 3,9 |

| 3,53 | 2,75 | 4,5 |

| 4 | 3,15 | 5,2 |

| 5 | 4 | 6,5 |

| 5,7 | 4,65 | 7,4 |

| 6 | 4,95 | 7,8 |

| 6,99 | 5,85 | 9,1 |

| 8 | 6,75 | 10,4 |

| 8,4 | 7,15 | 10,9 |

| 9 | 7,7 | 11,7 |

| 10 | 8,65 | 13 |