What O-ring groove?

21 Aug

What O-ring groove? - our customers ask

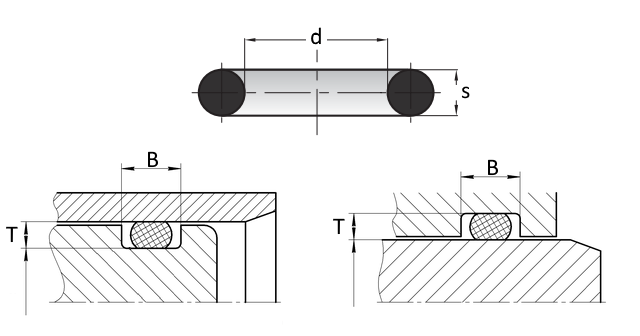

The depth of the groove should be adapted to the specific purpose - this will make the seal impermeable. The ratio of the seal cross-section diameter (s) to the groove depth determines the preload. If you are looking for a static seal, the initial stress should be between 15 and 30%. However, in the case of dynamic use, the best solution will be to choose a larger groove depth, and hence a smaller initial stress (usually from 6 to 20%).When determining the width of the groove, consider:

- O-ring diameter (s)

- oval form formed after assembly

- free space, which is necessary to ensure even pressure

It is important to prevent the groove from overfilling - the O-ring should fill it to a maximum of 85%, leaving room for possible increase in volume.

The table gives the groove parameters for static use (depth and width):

| s O-ring thickness | T groove depth | B groove width |

| 1,5 | 1,1 | 1,9 |

| 1,6 | 1,2 | 2,1 |

| 1,78 | 1,3 | 2,3 |

| 2 | 1,5 | 2,6 |

| 2,4 | 1,8 | 3,1 |

| 2,5 | 1,9 | 3,2 |

| 2,62 | 2 | 3,4 |

| 3 | 2,3 | 3,9 |

| 3,53 | 2,75 | 4,5 |

| 4 | 3,15 | 5,2 |

| 5 | 4 | 6,5 |

| 5,7 | 4,65 | 7,4 |

| 6 | 4,95 | 7,8 |

| 6,99 | 5,85 | 9,1 |

| 8 | 6,75 | 10,4 |

| 8,4 | 7,15 | 10,9 |

| 9 | 7,7 | 11,7 |

| 10 | 8,65 | 13 |